Decarbonizing Steel: Why the BF-EAF Dual Mandate Must Be the Focus | Our Strategic View Part 1

Global warming is the world's most urgent and critical challenge. In response, the global community, unified under the Paris Agreement, is driving various initiatives toward Net Zero with the ultimate goal of achieving a decarbonized future.

The steel industry is central to this effort, standing out as a major contributor to Greenhouse Gas (GHG) emissions, particularly carbon dioxide (CO2). Decisively reducing these emissions is now drawing significant global attention.

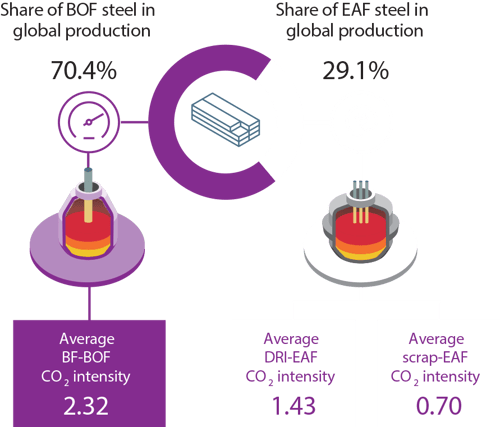

In general discussions about decarbonization, Electric Arc Furnaces (EAFs), which recycle scrap steel, tend to receive more attention than Blast Furnaces (BFs), which rely on iron ore and coal, as EAFs are often considered the lower CO2 option.

As one to ONE Group with over 90 years of expertise in steel-tube manufacturing in Japan and its value chain, we recognize the essential roles of BFs and EAFs in the journey toward Net Zero. A decarbonized society relies on advancing both technologies simultaneously and in a balanced manner.

Given the current condition of the steel industry, we will outline our views on the roles and importance of BFs and EAFs in achieving the global climate mandate.

The Steel Industry's Role in the Global Net Zero Mandate

The worldwide aim for climate action is to restrict temperature rise to the crucial 1.5℃ target established by the Paris Agreement. The crucial timeline, based on the IPCC, is to achieve net-zero CO2 emissions globally by 2050.

This commitment is cemented by National Net Zero pledges. Over 150 countries, including the EU, the US, and Japan, target net-zero emissions by 2050, while major emitters like China (2060) and India (2070) have set later targets, according to NDCs, UNFCCC.

The steel industry is central to this challenge, accounting for approximately 38% of industrial CO2 emissions, making its deep decarbonization efforts indispensable. A significant challenge is that over 90% of the industry's CO2 emissions originate from the traditional BFs process.

See also: What Is "Optimal" Sustainability in the Steel Industry?

As a result, there is significant emphasis on EAFs. These EAFs, which recycle scrap steel, provide a distinct benefit by cutting CO2 emissions down to about one-quarter of what traditional BFs emit, thus significantly reducing the environmental impact.

Two Major Steelmaking Routes: BF vs. EAF

Steel production methods vary significantly by nation due to resource availability. Countries like China and Japan, which utilize substantial amounts of virgin iron ore, mainly employ the Blast Furnace-Basic Oxygen Furnace (BF-BOF) method. This accounts for high percentages of their crude steel output (e.g., China at nearly 90% and Japan over 70%. Source: World Steel Association).

In contrast, regions with abundant local scrap steel—like the U.S. and much of the EU—mostly rely on the EAF route.

- BF Method: Carbon, often in the form of coke, is used to take iron from iron ore. This molten iron is then purified in a converter to make steel. After that, it is cast and processed.

- EAF Method: The Electric Arc Furnace mainly uses scrap steel. The heat from electric arcs melts the scrap, turning it into liquid steel, which is then processed.

Why Both BFs and EAFs Are Indispensable for Global Supply

The EAF process is fundamentally based on using the heat of electricity to melt end-of-life steel products and transform them into new steel. Iron is a unique resource found in vast quantities on Earth and can be recycled repeatedly without degradation. EAF technology maximizes this inherent characteristic, enabling the continuous recycling of steel products while significantly suppressing CO2 emissions. This robust iron cycle, facilitated by EAFs, contributes profoundly to achieving carbon neutrality and a decarbonized society.

Despite the push for decarbonization, global steel demand is expected to continue expanding for the foreseeable future, driven by rapid economic development and infrastructure construction in emerging economies.

See also: CO2 intensity | Glossary

Scrap Steel's Inherent Supply Challenge

The challenge is that scrap steel, the primary raw material for EAFs, is recovered from steel products that have reached the end of their service life. Consequently, its availability is inherently limited and currently concentrated primarily in developed nations. Although scrap volumes are increasing annually, they cannot meet total global demand solely from existing stocks.

To fulfill steadily growing global demand and secure the essential virgin iron supply, the BF route remains indispensable as a primary production source.

Crucially, BFs and EAFs are truly complementary in fulfilling society's overall iron demand. By continuously supplying new steel, the BF route directly accumulates the stock of future scrap steel that enables the long-term EAF recycling cycle.

Therefore, a balanced, dual strategy evolving both technologies is vital for achieving sustainable supply and deep Net Zero goals.